Our production includes:

- Design and Development

- Cutting of wire weaves

- Punching

- Forming

- Welding / Soldering / Gluing

- Cleaning

- Quality assurance

- Warehouse / Dispatch

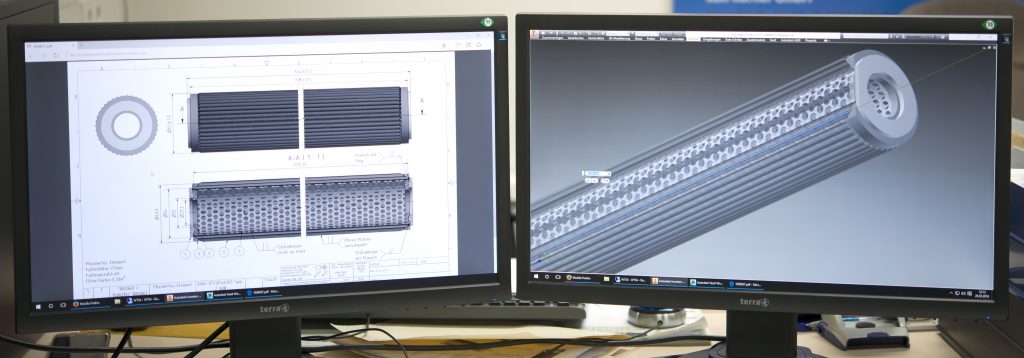

Design and Development

Everything from one source: development and design, own tool construction, manufacture and distribution.

Every filter element is designed accurately in 3D and drawn.

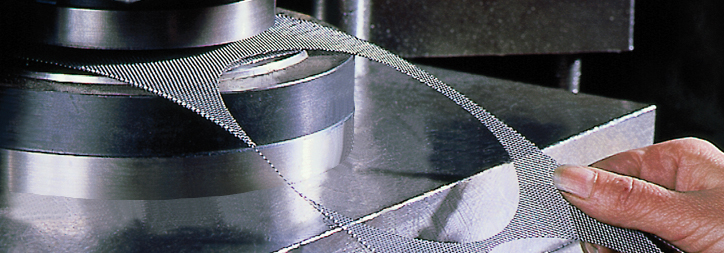

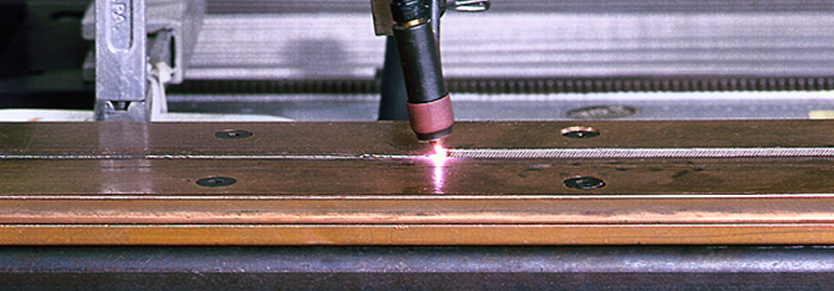

Cutting of wire cloths

Our wire cloths can be cut in length and width according to customer’s request.

Depending on the demand we use:

• Blade Cutter

• Roller Cutter

• Plasma Cutter

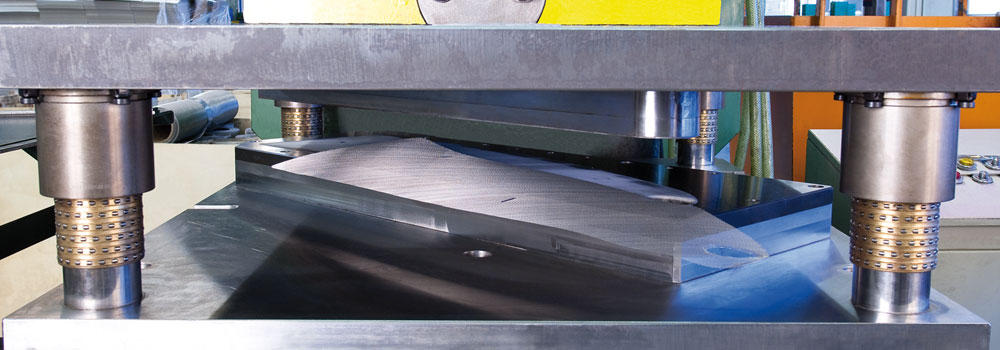

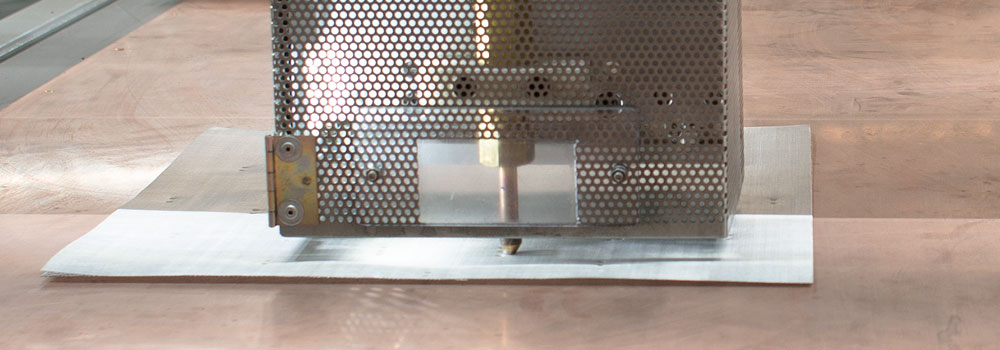

Punching

With our various punching machines and tools we are able to manufacture almost all established dimensions and shapes. For special requirements we construct our own tools.

In following production steps the screens can be framed or spot welded.

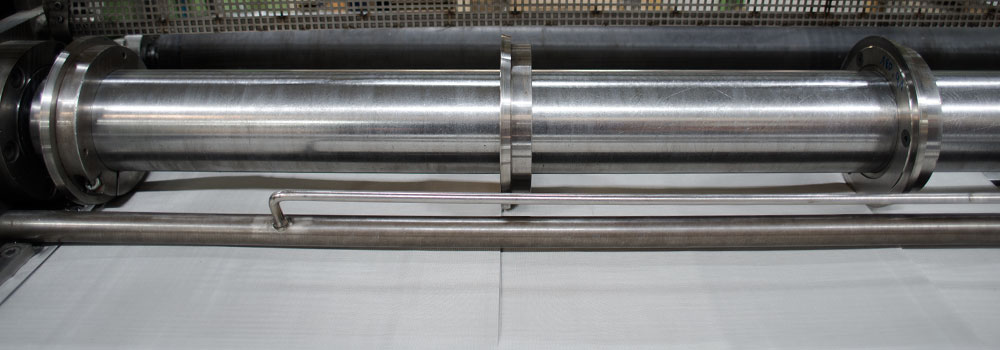

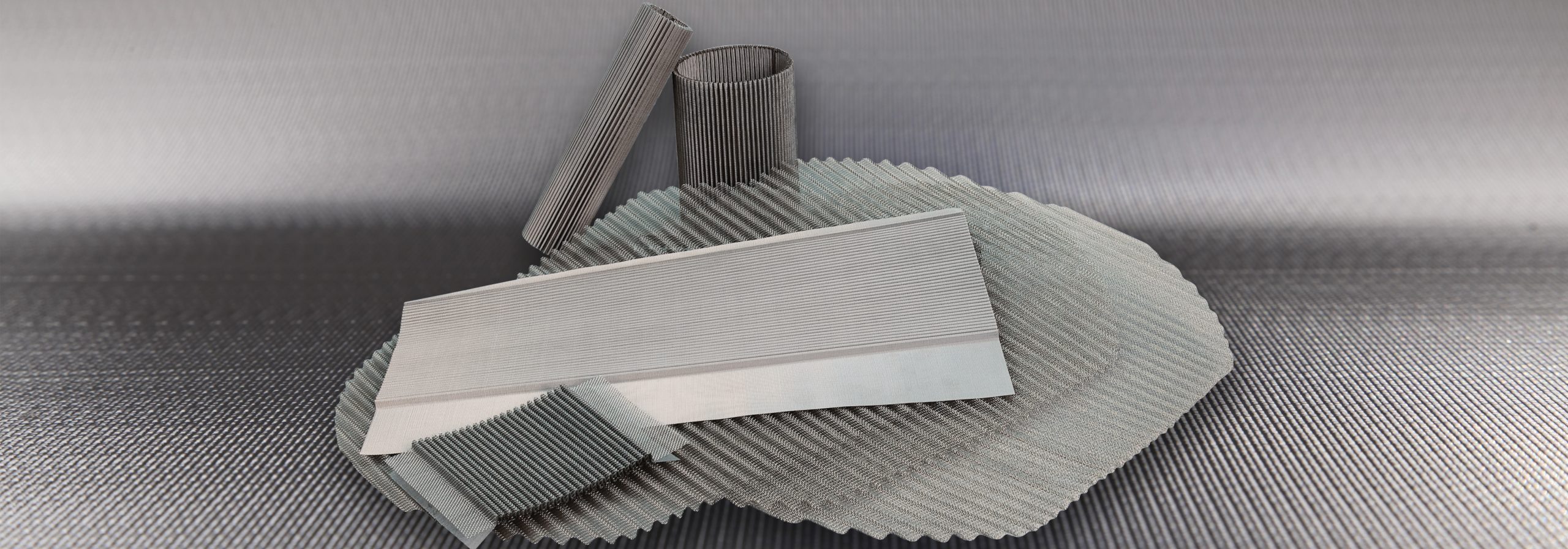

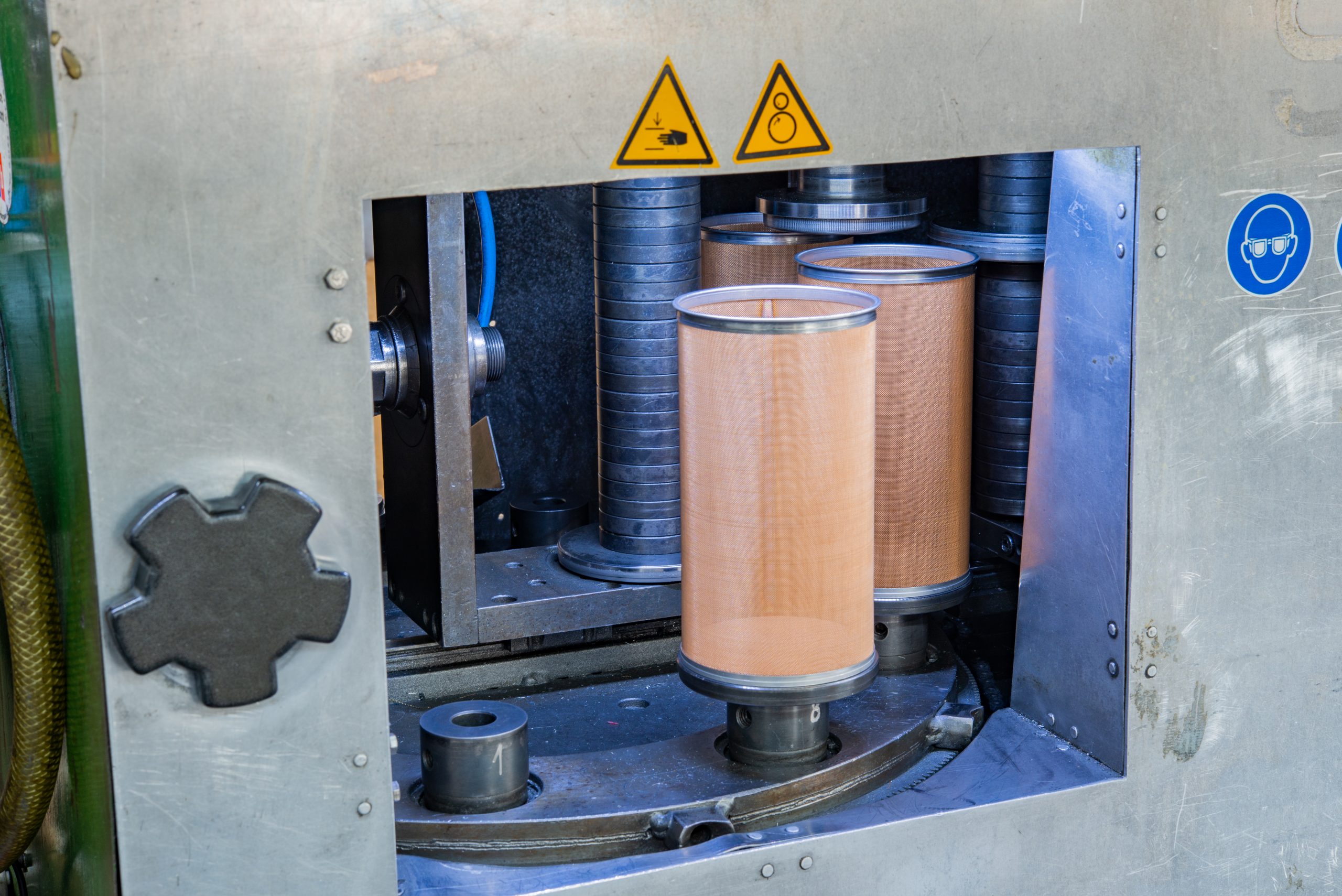

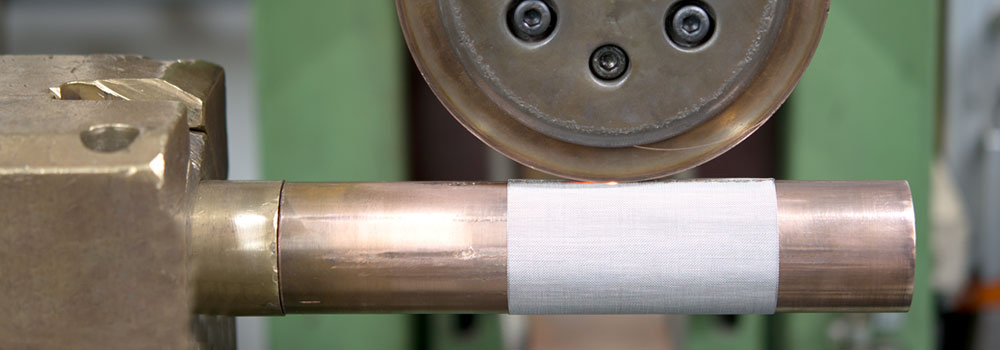

Forming

Our wire cloths can be formed to various elements. Cylindrical, conical, deep-drawn or pleated. Our flexible machinery enables us to manufacture almost every design.

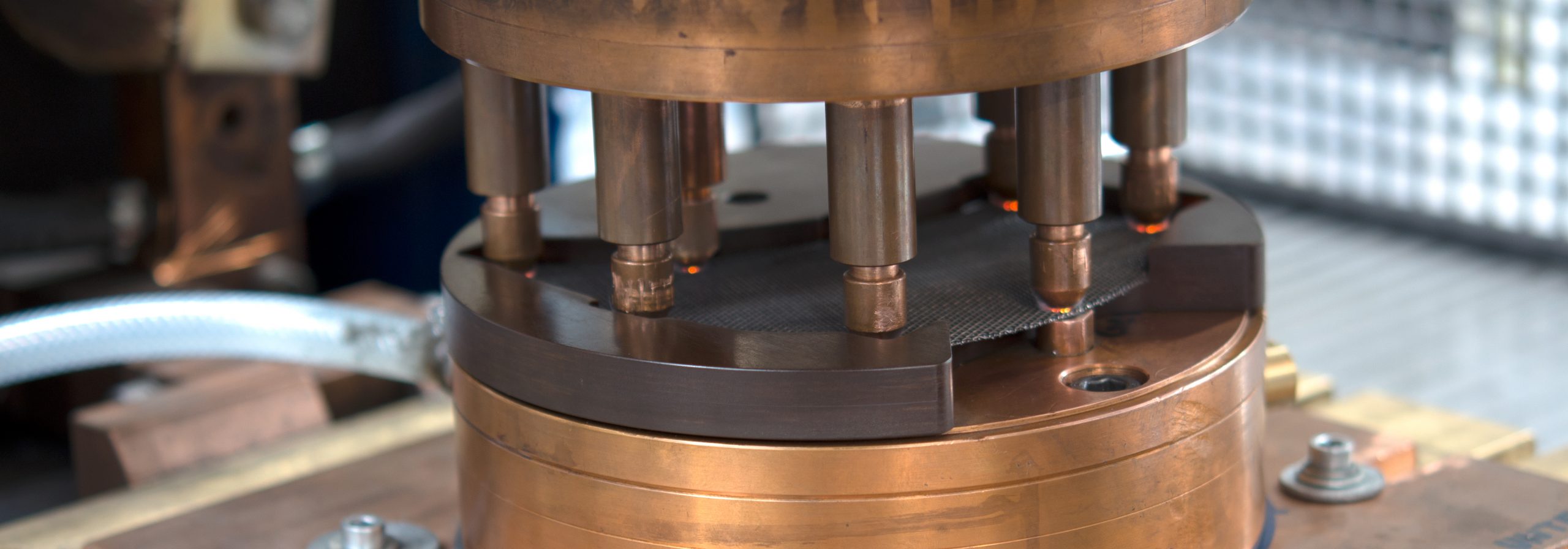

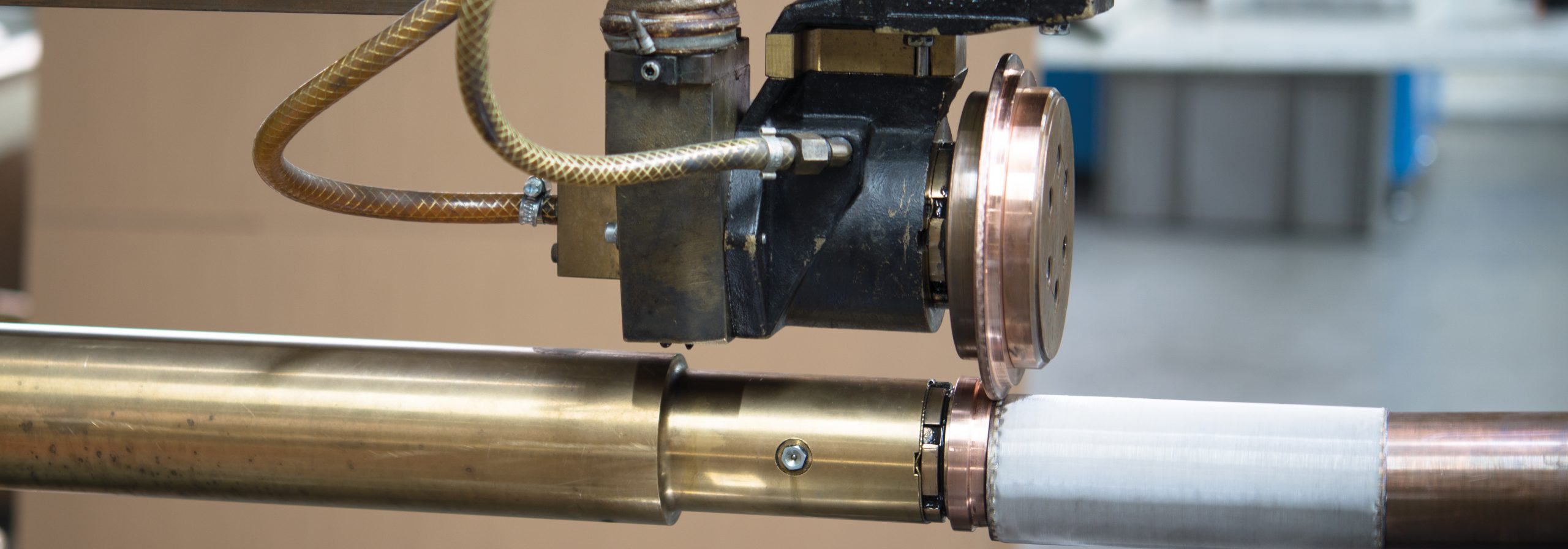

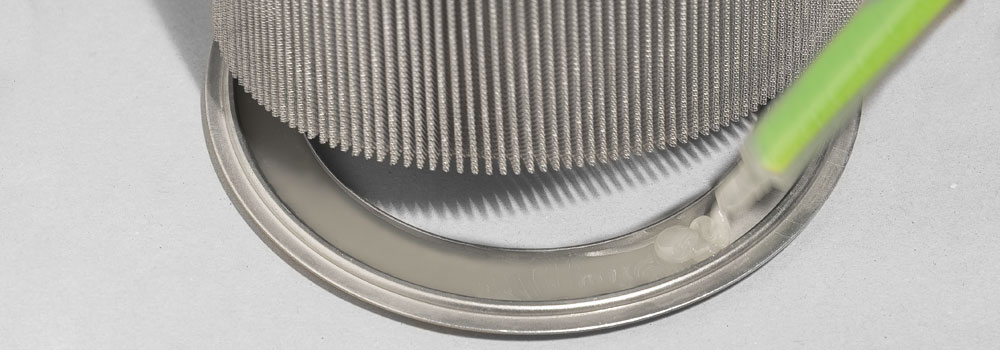

Welding / Soldering / Gluing

We dispose of the optimal joining technology for each element:

• WIG

• plasma welding

• cylindric seam welding, head seam welding

• spot welding

• soldering

• gluing

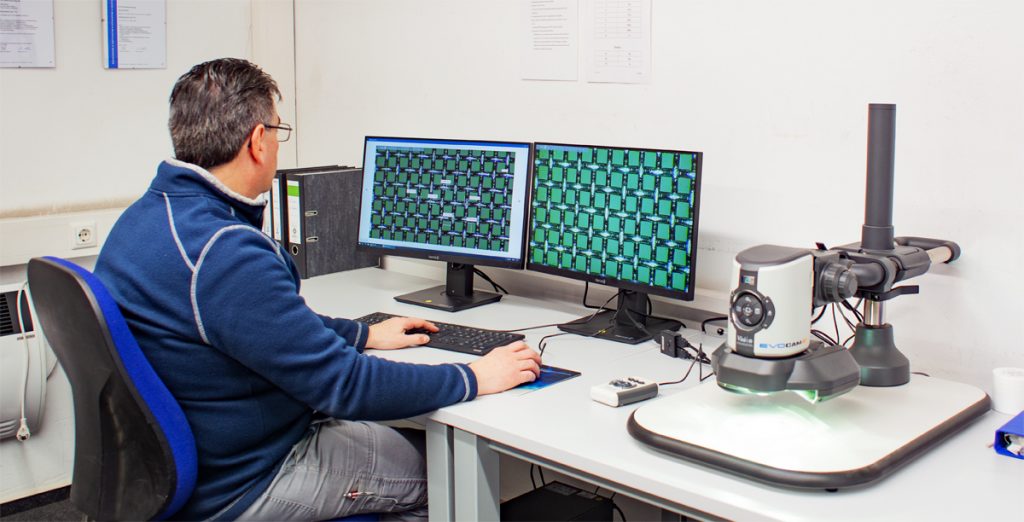

Quality assurance

Our products are subject to constant quality control starting from the incoming goods over the manufacturing process up to the final product, ready for dispatch.

Warehouse / Dispatch

Our well-sorted warehouse enables us to realise short delivery times. Common wire cloth styles are permanently available and can be converted to elements or shipped as rolled-goods immediately.

Suitable packaging adapted to the various elements is a must.