We have a well-stocked warehouse with wire-cloth from our own production in all common materials enabling us to respond quickly to our customers needs. Individual specifications can be specially produced on request.

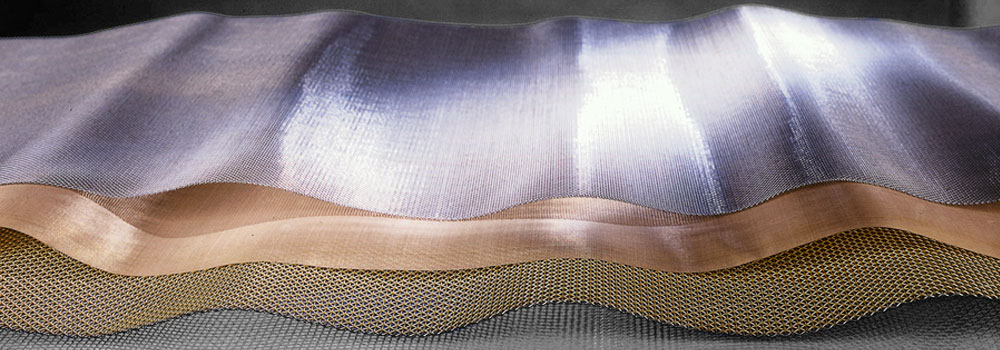

| Material: | stainless steel, plain steel, galvanized steel, copper, brass, phosphorus bronze, special alloys |

| Mesh width: | 5 µm to 10 mm (other dimensions on request) |

| Fabric width: | Standard widths: 1000, 1220, 1300, 1524 mm other on request |

| Scope: | as mother rolls or cut to size on customer‘s request |

Kinds of weaving

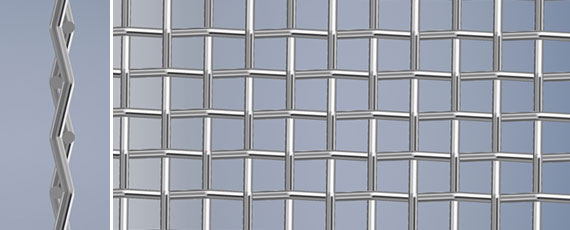

Plain weave

The most famous kind of weaving with particularly exact apertures. Warp and weft wires are woven over and under each other in a continuous alteration.

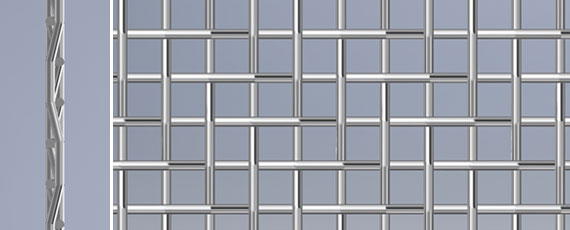

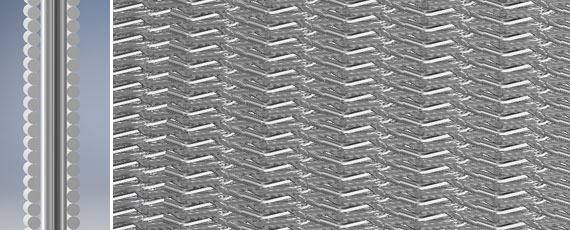

Twilled weave

In the twilled weave each warp and weft wire is woven over and under two. Where comparatively small apertures in combination with strong wires are required.

Plain dutch weave

Wire filter cloth, woven in a plain weave pattern having few and thicker warp wires and many and thinner weft wires, beaten closely together.

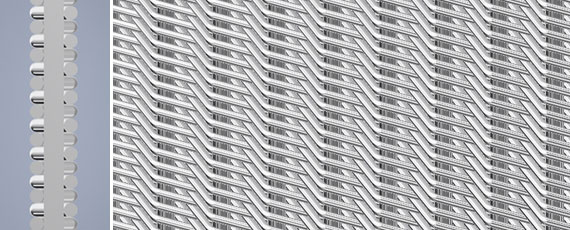

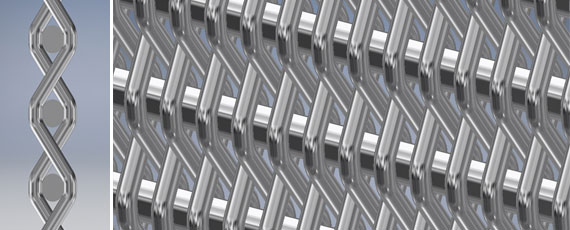

Twilled dutch weave

Twilled Dutch is of a similar construction to plain Dutch i.e. fewer thick warp wires, many thin weft wires, except the weave pattern is twilled which allows the maximum number of weft wires. Dutch twill is a surface filtration media and allowing the smallest openings. Smooth surface, very solid, specially used for finest filtration.

Reversed plain dutch (PZ) / Reversed twilled dutch (KPZ)

This is the reverse of plain dutch. The largest number of wires is found in the warp and the lesser number in the weft direction. The weft wires are much thicker than the warp wires. This construction is characterised by high stability at good troughput and excellent regeneration.